The Ultimate Multi-functionality Enabler – Surface Activated® Polymers

Satellite Aerospace and Defense Industries

The competitive nature of technology companies – in particular, Satellite, Aerospace and Defense Industries – demand components be smaller, smarter, lighter and more cost-effective. That’s a tall order made achievable with SAT Plating’s Surface Activation® and SelectPlate™ technology.

It wasn’t that many decades ago that the only engineers obsessed with weight reduction in their products were a rocket, aircraft, and Formula One designers. These people understood that there were direct and valuable rewards of increased performance for each gram of weight reduction.

Today, things that were formerly of metal (even lightweight aluminum or magnesium) are being converted to polymers and polymer composites. Now, myriad products are benefiting from “light-weighting” or “mass reduction”, due to the development of new technologies that leverage the use of high-performance composites. However, the biggest payoff is enabling designers to compress multi-discipline technologies into a single monolithic component while using the best plastics to achieve optimal price and performance for their products.

SelectPlate™: Best-in-Class Metal Plating

SAT Plating’s proprietary Surface Activation® and SelectPlate™ technology allow us to deliver best-in-class metal plating deposits on the most advanced composite and high-performance polymers in the world.

Polymers that were once considered “unplateable” can now be used to address issues such as weight, usability, functionality, and strength. These include plastics such as PEEK, Ultem®, Carbon Fiber, Polyimide, Cyanate Ester, 3D materials, and many others.

The keystone to our SelectPlate™ technology is Surface Activation® processing. When selectively applied to polymers, the Surface Activated® areas can be discriminately plated for Functional – Structural – and Electronics purposes.

Among the many Multi-Functional | Structural | Performance features achievable are:

- Conductivity

- Corrosion Resistance

- Abrasion Resistance

- Charging Circuits

- Salt Spray Survivability

- Wear / Impact Resistance

- Antennas

- Chemical Resistance

- Permeation Barrier

- Microwave Guides

- UV Protection

- Superior Adhesion

- RFI / EMI Shielding

- Anti-microbial

Simply put, Surface Activation® and SelectPlate™ can remove complexity, increase efficiencies, reduce mass and enable more robust multi-functional component architecture.

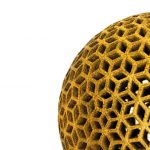

Plating Plastic Satellite Microwave Antennas

The complex geometries of structures such as antennas, waveguides, and inductive coils lend themselves naturally to be converted from machined metal to injection molded, or additive manufactured polymers. Satellite microwave antenna and receiver arrays can weigh less when made of polymer, but plastic has none of the conductive and attenuation characteristics of metals. Therefore, electroplating of these structures, typically with a combination of copper and nickel, is required. This situation is a prime example of the cost/benefit of converting metal components to a polymer-based architecture.

For more information on how SAT can collaborate with your R&D Teams, please call us at 248.273.0037

© SAT Plating 2019