Our Surface Activated® SelectPlate™

Designed and developed for plastics that were considered “unplateable” like Ultem and PEEK, our proprietary process called SelectPlate™ allows us to metalize only where required to meet your product’s specifications.

The keystone to our SelectPlate™ technology is Surface Activation® processing. When selectively applied to polymers, the Surface Activated® areas can be discriminately plated for Functional – Structural – Appearance purposes.

Whether it’s plating for appearance, electrical conductivity, or EMI shielding, SelectPlate™ meets your needs. Plating selected areas on components has been done for years in the industry – often with inefficient and labor intensive methods, not to mention high scrap rates. Our SelectPlate™ methods are highly efficient, repeatable, and can scale to meet high-volume product demands. Expand your product’s capabilities and ask about SelectPlate™.

Simply put, SelectPlate™ can remove complexity, increase efficiencies, and reduce weight.

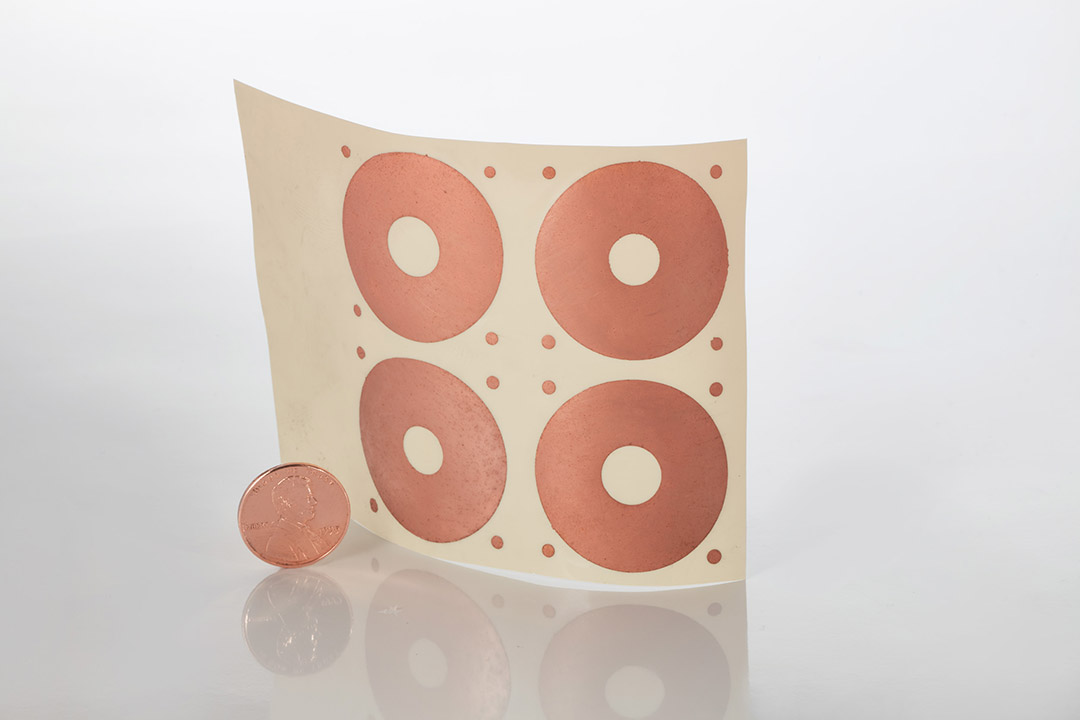

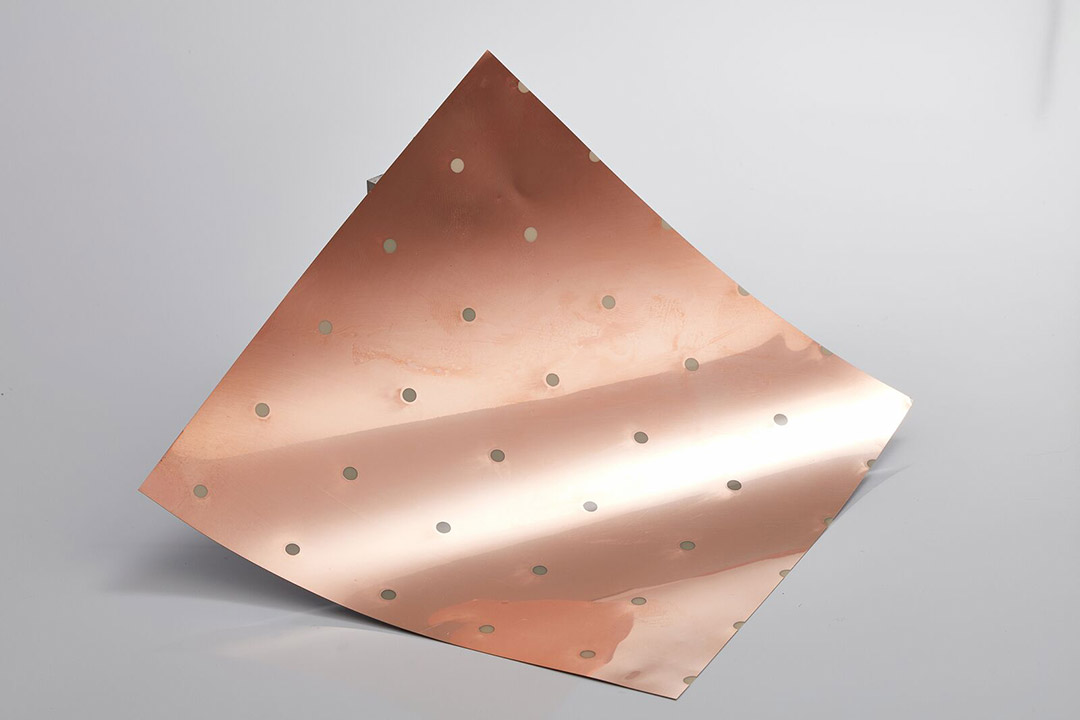

Examples of selectively plated parts

The drive for the creation of this process was the demand from customers in the aerospace, medical, and automotive industries for their products to meet consumer and manufacturing needs. Throughout the years, we have expanded the value our customers can bring to the market.

SelectPlate™ can compress multi-discipline technologies into a single monolithic component and remove post-process steps, such as soldering and bonding various parts together. This reduces the weight of products, and increases the efficiency of assembly, which is of supreme importance for manufacturing processes. Simply put, SelectPlate™ can remove complexity, increase efficiencies, and reduce weight.

In order to achieve a higher-quality product, things like electrical conductivity, signal detection, and localized heating must be improved. The improvement of these characteristics was always tricky since the list of usable biocompatible polymers was severely limited. This was mainly due to many polymers simply being unable to meet the performance requirements necessary to achieve these characteristics.

We are able to remove these barriers with our SelectPlate™ process, opening up the range of polymer choices. This gives engineers and manufacturers the ability to select the best polymers in the world to optimize their products, rather than choose from a previously narrow list of materials.

The plateable substrates we offer are as follows:

- PEEK – Polyetheretherketone

- Ultem – (PEI)

- Polypropylene (PP)

- Polyurethane (PUR)

- Polystyrene (PS)

- Polyester Polyvinyl Chloride (PVC)

- Polyether sulfone (PES)

- Polyethylene (PE)

- Polysulfone (PSU)

- Polyamides (Nylon)

- Polyimides (PI)

- Polyacrylate (PMMA)

With this advancement, we are now able to plate both an entire substrate, and the smaller and more intricate parts of a substrate that were not plateable in the past.